A steaming hot cup of ginger tea and rusk to dunk in to it, is a great way to start the day or a relaxing way to unwind in the evening. However, a recent viral video where workers in a rusk making unit were seen to be licking and stepping on the rusks before packing them has got us rethinking our routine.

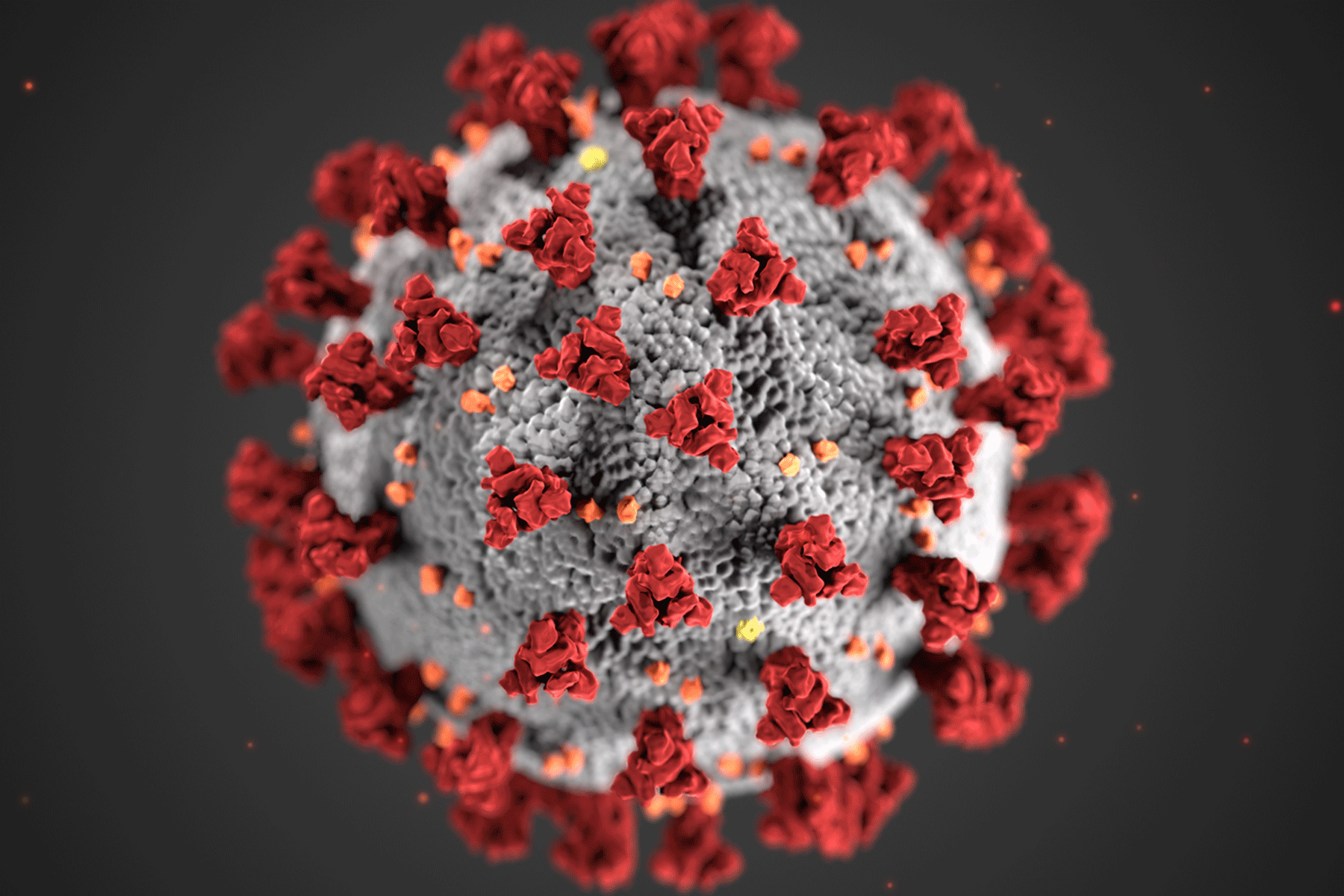

The lack of food safety measures being implemented in factories and other food units can prove to be detrimental to human health. Food safety refers to the assurance that food is fit for human consumption when used as intended. The adoption of Good Manufacturing Practices, Good Hygienic Practices, Hazard Analysis and Critical Control Point, ISO and other similar practices as may be stipulated by regulation, for the food company, is referred to as a Food Safety Management System.

Role of Food Packaging in Food Safety

Consumers, the media, regulators, and food business tend to focus on the product rather than the packaging’s safety, however packaging is an important part of the whole food safety process. Packaging is more important than ever as food distribution networks have become more global . Packaging ensures that the end product is safe and secure for consumption.

In order to establish a defense against packing defects, all manufacturers need to consider various elements.

- Firstly, examine the packaging and production process-

Only by evaluating and preparing for the factors at play in the packaging process, as well as ensuring that manufacturing methods adhere to all safety and quality regulations, can defences against an untoward incident be strengthened and any shortcomings in packaging be mitigated.

- Secondly, assess the likelihood of human error-

There are a number of enhancements that may be made to reduce human error in the food packing process. First, businesses must ensure that everybody who works with food or its packaging is well-versed in personal hygiene, equipment, utensils, and surface sanitisation, and the implications of malpractice. The ideal approach to do so is to implement a training programme that is suited to each company’s culture and personnel, as well as the particular risk environment of food preparation and packaging standards.

- Finally, examine your supply chain to confirm that the raw materials and value-added goods that go into your product satisfy international standards-

A manufacturer can determine the amount of food safety hazards related with a particular supply chain and packaging material by risk-assessing the packaging supplier in relation to its goods, processes, and customer base. Risk assessments allow for the assignment of various levels of due diligence requirements that suppliers must follow, as well as the identification of any early red flags in the food packaging process that may constitute a safety risk.

Food Packaging Standards with Respect to Food Handlers

A crucial step in preventing food-borne illness is the food handlers’ personal hygiene. These personal hygiene habits should become second nature to them when handling food.

- All food handlers must wear appropriate protective clothes, including a head covering, face mask, gloves, and footwear.

- Food handlers must wash their hands at the start of each food handling activity and soon after touching raw food or any contaminated substance, instrument, equipment, or work surface that could contaminate other food items, or after using the restroom.

- Hands must always be washed with antibacterial liquid soap and clean potable water, disinfected, and then dried with disposable paper towel.

- Food handlers should keep their nails and hair trimmed on a regular basis.

- In the food preparation and serving areas, no food handlers shall be smoking, spitting, chewing, sneezing, or coughing over any food.

- To avoid cross contamination, food handlers should not touch soiled cash notes/cards.

- While entering the food processing area, street shoes should not be worn inside.

- Food handlers must refrain from scratching their noses, running their fingers through their hair, rubbing their eyes, ears, and mouths, scratching their beards, and scratching various portions of their bodies. When such acts are inevitable, hands should be thoroughly cleansed before returning to work.

With different guidelines in place, one can only hope they are implemented efficiently and effectively. It is only through responsible action and awareness of food business owners that all of us can enjoy the little pleasures in life, like a hot cup of tea and clean, sanitary and hygienic rusks.

Food Manifest

Food Manifest

Leave a Comment

Your email address will not be published. Required fields are marked with *