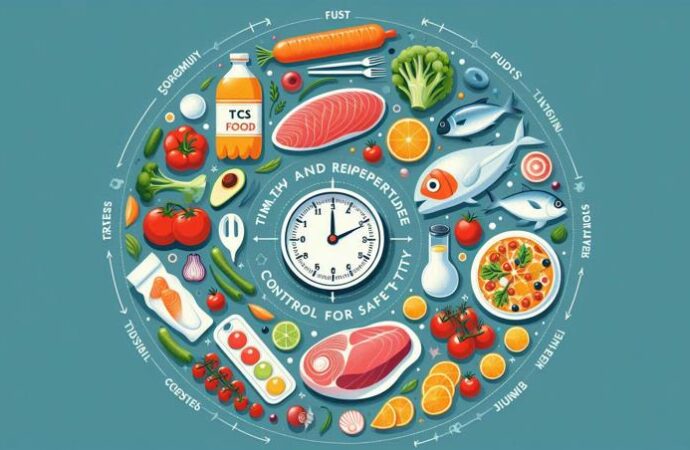

TCS Foods, or Time and Temperature Controlled Foods, encompass a category of perishable food items that require specific handling practices to maintain safety and quality. The term TCS signifies the critical factors of time and temperature that food handlers must manage to prevent the growth of harmful microorganisms. This understanding is essential for anyone involved in food preparation, from home cooks to professional chefs, as it directly impacts the prevention of foodborne illnesses and the overall quality of meals served.

What Are TCS Foods?

TCS Foods includes a variety of items that are particularly susceptible to spoilage and contamination. These foods contain the ideal combination of moisture, nutrients, and pH levels that allow bacteria to flourish. However, not all foods labelled as non-TCS are devoid of risk; many contain potential hazards, be they biological, physical, or chemical.

Understanding the nature of TCS Foods helps food handlers develop appropriate strategies for formulating, preparing, and serving food products safely. This responsibility is crucial for both food managers and handlers, as it helps prevent foodborne illnesses and reduces food waste.

Examples of Time and Temperature Controlled Foods or TCS foods are:

- Dairy products, including milk, cheese, sour cream, whipped butter, and ice cream

- Meats, poultry, and seafood

- Heat-treated plant-based foods, such as cooked onions, rice, baked potatoes, and soy products like tofu

- Cut fruits and vegetables, including melons, tomatoes, carrots, and leafy greens

- Raw seed sprouts

- Garlic-in-oil preparations

- Ready-to-eat (RTE) items, like fruits, baked goods, cooked pizza, and deli meats

Characteristics of TCS Foods

Several key characteristics define TCS Foods and influence their safety:

Acidity: Foods with low acidity, such as meats and dairy products, are more prone to bacterial growth if not stored and handled correctly. Conversely, acidic foods like citrus fruits or tomatoes can inhibit the growth of certain pathogens due to their lower pH levels.

Moisture Content: Moisture is another critical factor affecting TCS food safety. Foods with high moisture content, including fresh fruits, seafood, and cooked grains, provide an optimal environment for bacterial growth. Therefore, controlling moisture levels through proper refrigeration and storage is essential in preventing spoilage and foodborne illnesses.

Heat Treatment: Cooking TCS Foods to specific internal temperatures effectively kills harmful pathogens such as bacteria and parasites, ensuring that the food is safe for consumption. Heat treatment also extends the shelf life of certain foods, particularly canned goods.

Packaging: The type of packaging used for TCS Foods can significantly impact their safety. Airtight and vacuum-sealed packaging can prevent the entry of oxygen and spoilage microorganisms, extending the shelf life of these foods while avoiding cross-contamination during storage and transportation.

What makes TCS Foods Dangerous?

TCS Foods can be breeding grounds for harmful bacteria. Bacteria require three essential elements to grow: food, moisture, and warmth. While small amounts of bacterial growth in TCS Foods may not pose a significant threat, excessive growth can lead to foodborne illnesses. TCS Foods provides the necessary nutrients and moisture for bacteria to thrive. When combined with time and warmth, these foods can become dangerous.

Time plays a crucial role in bacterial growth. When bacteria have access to food, warmth, and moisture, their numbers can double every twenty minutes. After just four hours, most TCS Foods can reach a bacterial count that renders them unsafe to eat. The temperature range between 41°F and 135°F creates conditions ideal for rapid bacteria growth, often referred to as the temperature danger zone. TCS Foods in this range will quickly become hazardous if not managed correctly.

Best Practices for Keeping TCS Foods Safe

To ensure the safety of TCS Foods, food handlers should follow several best practices:

Temperature Monitoring: Maintain cold foods at 41°F or below and hot foods at temperatures above 135°F. This practice keeps foods out of the danger zone and helps prevent bacterial growth.

Rapid Cooling: After cooking, it is vital to cool foods quickly. Foods should transition from 135°F to 70°F within the first two hours, and then down to 41°F within four hours. This rapid cooling reduces the time food spends in the danger zone, minimizing the risk of bacterial growth.

Proper Thawing: Always thaw frozen food in the refrigerator rather than at room temperature. Thawing at room temperature can allow the outer layers of the food to reach temperatures that encourage bacteria growth while the inside remains frozen.

Storage Guidelines: Store TCS Foods at the appropriate temperatures. Cold foods should be held at 41°F or below, while frozen foods must remain frozen to prevent thawing. Regularly check and calibrate refrigerator and freezer temperatures to ensure they are functioning correctly.

Educate Your Team: Continuous education for all food handlers is essential. Ensure that everyone understands the importance of TCS Foods, the risks involved, and the best practices for safe food handling.

Conclusion

Understanding TCS or Time and Temperature Controlled Foods and their safety requirements is crucial for anyone involved in food preparation. By recognizing the key characteristics that make these foods vulnerable to contamination and implementing proper handling practices, we can significantly reduce the risk of foodborne illnesses. Maintaining the right temperatures, rapidly cooling foods, and ensuring proper storage are essential steps in keeping TCS Foods safe.

By prioritizing education and awareness, food handlers can foster a culture of safety in both home kitchens and commercial food establishments. This commitment not only protects consumers but also enhances the overall quality of food served, ensuring that meals are both safe and enjoyable.

Food Manifest

Food Manifest