Determining the shelf life of processed foods is essential for maintaining food safety, quality, and consumer satisfaction. Shelf life refers to the period during which a product remains safe for consumption while preserving its sensory qualities, such as taste, texture, and appearance. This is particularly challenging for processed foods with extended shelf lives or modified ingredients, as they often undergo complex production and packaging processes. Accurately estimating shelf life not only helps in maintaining food safety by preventing spoilage or contamination but also ensures that products retain their nutritional value and visual appeal throughout their lifespan, making it a critical aspect of food manufacturing.

What is Shelf Life?

Shelf life is the period between production or packaging and when food becomes unfit for consumption due to spoilage, contamination, or a loss of quality. In India, the Food Safety and Standards Authority of India (FSSAI) defines shelf life as the time until food no longer remains safe for consumption, typically indicated by microbiological contamination or significant changes in appearance, texture, or taste. The FSSAI regulates food products to ensure they meet safety and quality standards, with clear guidelines on labelling shelf life, expiration dates, and best-before dates to protect consumer health and ensure food safety across the country.

Factors Affecting Shelf Life of Processed Foods

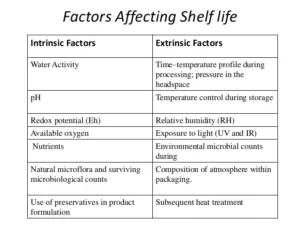

Several factors influence the shelf life of processed foods, categorized into intrinsic (inherent to the product) and extrinsic (external conditions).

Formulation of Processed Foods

The formulation, including ingredients like preservatives, antioxidants, and stabilizers, plays a major role in shelf life. Products with high moisture or fat content, like dairy or sauces, spoil faster than dry foods like chips or cereals. Choosing ingredients that prevent spoilage or oxidation is key for manufacturers.

Processing Techniques

The method used to process foods also affects shelf life. Techniques such as pasteurization, canning, freeze-drying, and vacuum sealing help extend shelf life by preventing microbial contamination and slowing chemical changes. Canned goods, for example, are processed at high temperatures to destroy harmful microorganisms and remain safe longer.

Packaging of Processed Foods

Packaging protects processed foods from external factors like light, moisture, and air, which accelerate spoilage. Modified atmosphere packaging (MAP), where air is replaced with gases like nitrogen, can help slow oxidation and microbial growth. Vacuum-sealing and airtight packaging help preserve texture and flavour.

Storage Conditions

Proper storage is crucial to maintaining shelf life. Temperature, humidity, and light exposure all impact food quality. For example, perishable foods like frozen meals or dairy products require refrigeration, while dry foods like snacks must be stored in dry conditions to avoid moisture-induced spoilage.

Expiration Date vs. Best By Date

When determining the shelf life of processed foods, two key terms often come into play: expiration date and best-by date. These terms help consumers understand the safety and quality of a product over time.

- Expiration Date: This date is commonly found on perishable foods and indicates when a product may pose health risks if consumed due to microbial contamination or spoilage. Manufacturers need to communicate this date, ensuring consumers understand when a product is no longer safe to eat.

- Best By Date: For more stable, processed foods, the best-by date is used to signify when a product may begin to lose quality, such as a change in flavour or texture. Importantly, products are still safe to consume past this date, but their sensory appeal may not be at its peak. This distinction helps in managing consumer expectations and reducing food waste.

Both of these dates are critical in understanding how long processed foods maintain their desired quality and safety, and they’re heavily influenced by various intrinsic and extrinsic factors.

Intrinsic and Extrinsic Factors Affecting Shelf Life

When determining the shelf life of processed foods, understanding the various intrinsic and extrinsic factors that affect a product’s stability is crucial.

Intrinsic Factors

Intrinsic factors are inherent characteristics of the food itself that directly influence its shelf life:

- Ingredients: The choice of preservatives, antioxidants, and stabilizers plays a significant role in extending a product’s lifespan. These ingredients slow down the degradation of the product and prevent spoilage.

- Water Activity: Foods with higher moisture content, such as sauces or soups, are more prone to spoilage compared to low-moisture foods like dry cereals or chips. This makes water activity a key factor in shelf life determination.

- pH Level: Foods with low pH, such as pickles or citrus-based products, tend to resist bacterial growth and thus have a longer shelf life. In contrast, products with a higher pH are more vulnerable to microbial contamination.

Extrinsic Factors

Extrinsic factors refer to external conditions that impact the quality and safety of processed foods:

- Temperature: Heat accelerates microbial growth and spoilage. Therefore, maintaining proper temperature conditions, such as refrigeration or freezing, is essential for prolonging shelf life.

- Light: Exposure to light can degrade sensitive food components like fats and oils, leading to rancidity and flavour loss. Packaging that blocks light can help preserve the product’s sensory qualities and extend its usability.

- Humidity: Excess moisture can cause mould growth and spoilage, while extremely dry conditions can lead to staleness in food products. Proper packaging and storage conditions help control humidity and maintain the product’s quality.

Methods for Determining Shelf Life

Manufacturers use several methods to estimate shelf life and ensure food safety.

- Real-Time Studies: Products are stored under typical conditions and monitored over time. While accurate, these studies take time and may not reflect all real-world variables.

- Challenge Tests: Pathogens or microorganisms are introduced to simulate real-life conditions. This method assesses safety but doesn’t account for all spoilage factors.

- Accelerated Shelf Life Testing (ASLT): Conditions like temperature and humidity are altered to speed up spoilage and estimate shelf life faster. Although this method is cost-effective and versatile, it may not fully replicate real-world conditions.

- Predictive Microbiology: Mathematical models predict how microorganisms behave under varying conditions. This method helps develop new products but can be complex and may not always be precise.

Conclusion

Determining the shelf life of processed foods involves understanding and controlling factors like formulation, processing, packaging, and storage. Manufacturers use various methods to predict shelf life, ensuring products remain safe, nutritious, and high-quality. As processed food consumption continues to grow, accurate shelf life determination is essential for minimizing waste, maintaining food safety, and ensuring consumer satisfaction.

Food Manifest

Food Manifest