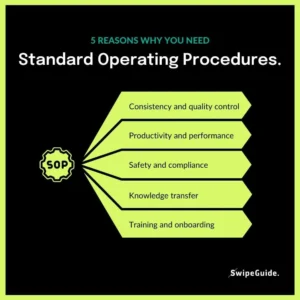

In the fast-paced and highly regulated food industry, consistency, safety, and quality are paramount. Achieving these standards requires food manufacturers to adhere to strict guidelines and processes. This is where Standard Operating Procedures (SOPs) come into play. SOPs are written instructions that outline the steps required to carry out various tasks, ensuring that every aspect of production, from food safety to quality control, is standardized. However, many food manufacturers face challenges in creating, implementing, and maintaining effective SOPs. Problems such as lack of clarity, inconsistent application, and inadequate training can hinder the efficiency of these procedures. Despite these challenges, SOPs remain an essential tool for achieving operational success in the food industry. This article explores the importance of SOPs in food manufacturing, identifies common problems, and suggests solutions to enhance their effectiveness.

The Importance of SOPs in Food Manufacturing

Consistency

SOPs ensure that employees follow the same procedures, leading to consistent product quality. By using standardized guidelines, businesses can produce products with the same taste, texture, and appearance every time.

Compliance

SOPs help businesses meet food safety regulations and industry standards, such as HACCP (Hazard Analysis Critical Control Point). They also facilitate obtaining certifications and passing audits, ensuring compliance with legal and quality standards.

Efficiency

Clear tasks in SOPs make processes more efficient. Employees know exactly what to do, reducing confusion and mistakes. SOPs also simplify employee training, enabling new workers to quickly understand their roles.

Risk Management

SOPs reduce risks by providing clear instructions that prevent errors. They are crucial in maintaining food safety by ensuring tasks like cleaning, handling, and cooking are done correctly.

Documentation

SOPs act as records of processes, which are essential for audits, inspections, and quality control. They provide proof that tasks are carried out according to established procedures.

Types of SOPs in Food Manufacturing

SOPs cover various aspects of food production, including:

- Food Safety SOPs: Procedures for cleaning equipment, sanitizing facilities, and controlling temperatures.

- Quality Control SOPs: Guidelines for checking raw materials, inspecting products, and maintaining consistency.

- Manufacturing SOPs: Processes from ingredient preparation to packaging, ensuring each step follows the correct procedure.

- Maintenance SOPs: Instructions for maintaining and repairing equipment to minimize downtime.

- Waste Management SOPs: Guidelines for managing waste materials and ensuring proper disposal by environmental regulations.

Benefits of SOPs

SOPs play a critical role in food manufacturing, offering several benefits:

Improved Product Quality

SOPs ensure consistent product quality by standardizing tasks, which reduces variations in taste, texture, and appearance. Customers receive the same product every time.

Increased Efficiency

SOPs streamline operations, reducing the need for retraining and simplifying task completion. Employees can work faster and more accurately when they follow clear instructions, saving time and resources.

Regulatory Compliance

SOPs help businesses comply with food safety laws and industry regulations. Clear documentation helps businesses pass inspections and audits while ensuring adherence to quality standards.

Reduced Errors

By providing detailed instructions, SOPs minimize mistakes. When employees know exactly what to do, errors become less likely, improving food safety and production efficiency.

Better Employee Training

SOPs serve as valuable training tools. New employees learn procedures quickly, and existing staff stays updated on changes. SOPs ensure all employees work toward the same goals.

Accountability

SOPs create accountability by defining responsibilities and providing documentation of actions taken. This makes it easier to track processes and identify areas for improvement.

Best Practices for Writing and Implementing SOPs

Effective SOPs are crucial for ensuring safety and efficiency. Following best practices can help enhance their effectiveness:

Keep It Simple and Clear

Write SOPs in simple, easy-to-understand language. Avoid jargon unless it’s clearly defined. Clear, straightforward instructions are more effective.

Make SOPs Accessible

Ensure employees can easily access SOPs, whether through printed copies or digital versions on company systems.

Involve the Right People

Involve the employees who will use the SOPs when creating or updating them. Their input ensures the procedures are practical and address any issues early on.

Review Regularly

SOPs should be reviewed and updated regularly to remain relevant. Set a schedule to review SOPs to ensure they align with changes in regulations, technology, or processes.

Train Employees

Provide regular training on SOPs to ensure that employees understand their roles and how to follow the procedures. This reinforces the importance of SOPs and keeps everyone informed.

Encourage Feedback

Encourage employees to provide feedback on SOPs. They may have valuable insights on improving or simplifying the procedures. Feedback also helps identify areas where SOPs might be unclear or difficult to follow.

Conclusion

Standard Operating Procedures (SOPs) are vital for ensuring consistency, safety, and quality in food manufacturing. However, challenges such as unclear instructions, irregular updates, and lack of employee engagement can hinder their effectiveness. By addressing these issues through simple, clear writing, regular reviews, and involving employees in the process, manufacturers can improve the effectiveness of SOPs. Training staff and making procedures easily accessible further enhances their adherence and impact. When implemented properly, SOPs streamline operations, minimize errors, and ensure food products meet the highest standards every time. By addressing the challenges head-on, food manufacturers can develop stronger, more efficient systems that comply with regulations and improve overall product quality and safety.

Food Manifest

Food Manifest